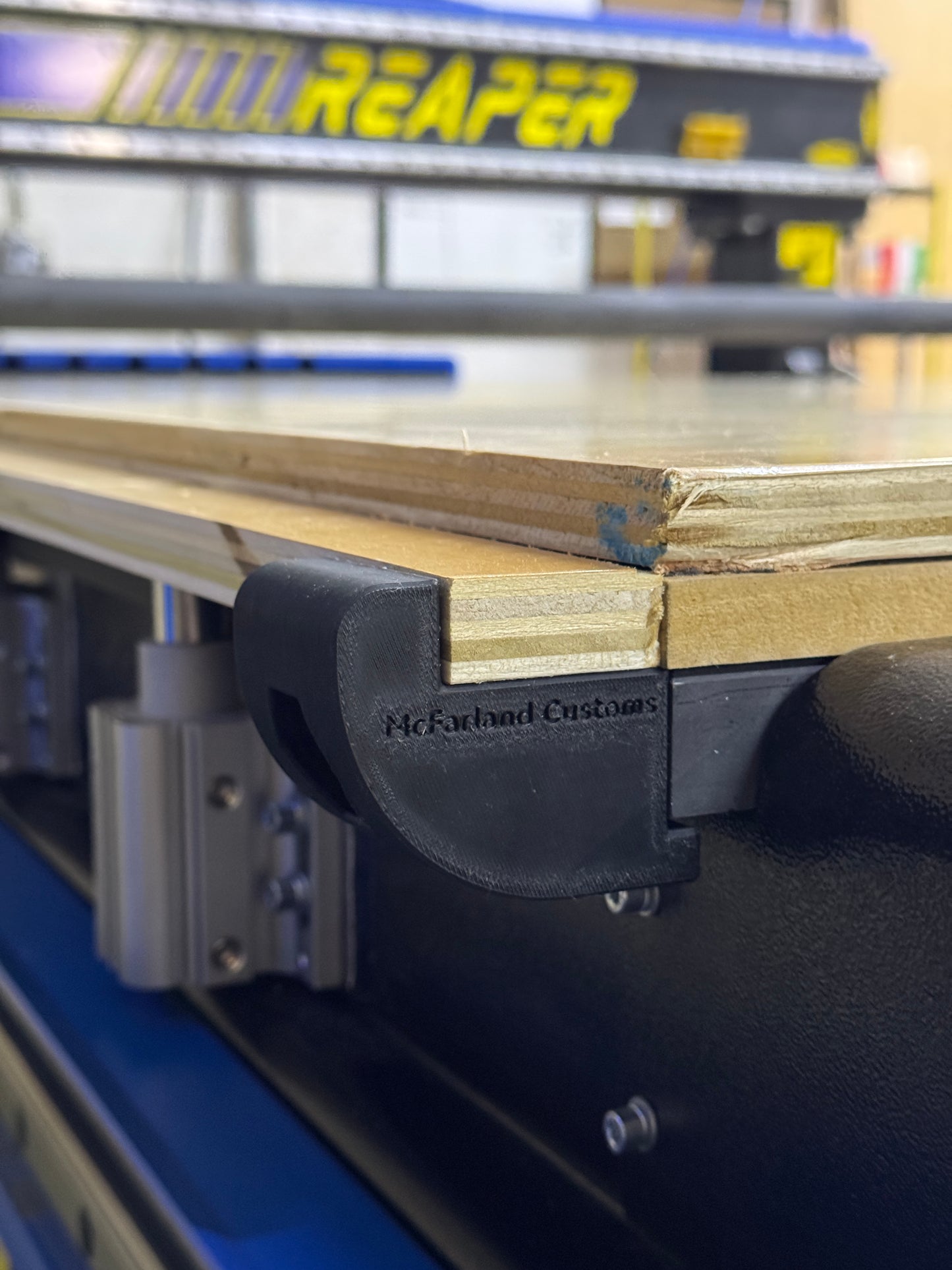

McFarland Customs

DustEdge Support Bracket

DustEdge Support Bracket

Couldn't load pickup availability

Solve Your CNC Dust Problem with DustEdge Brackets

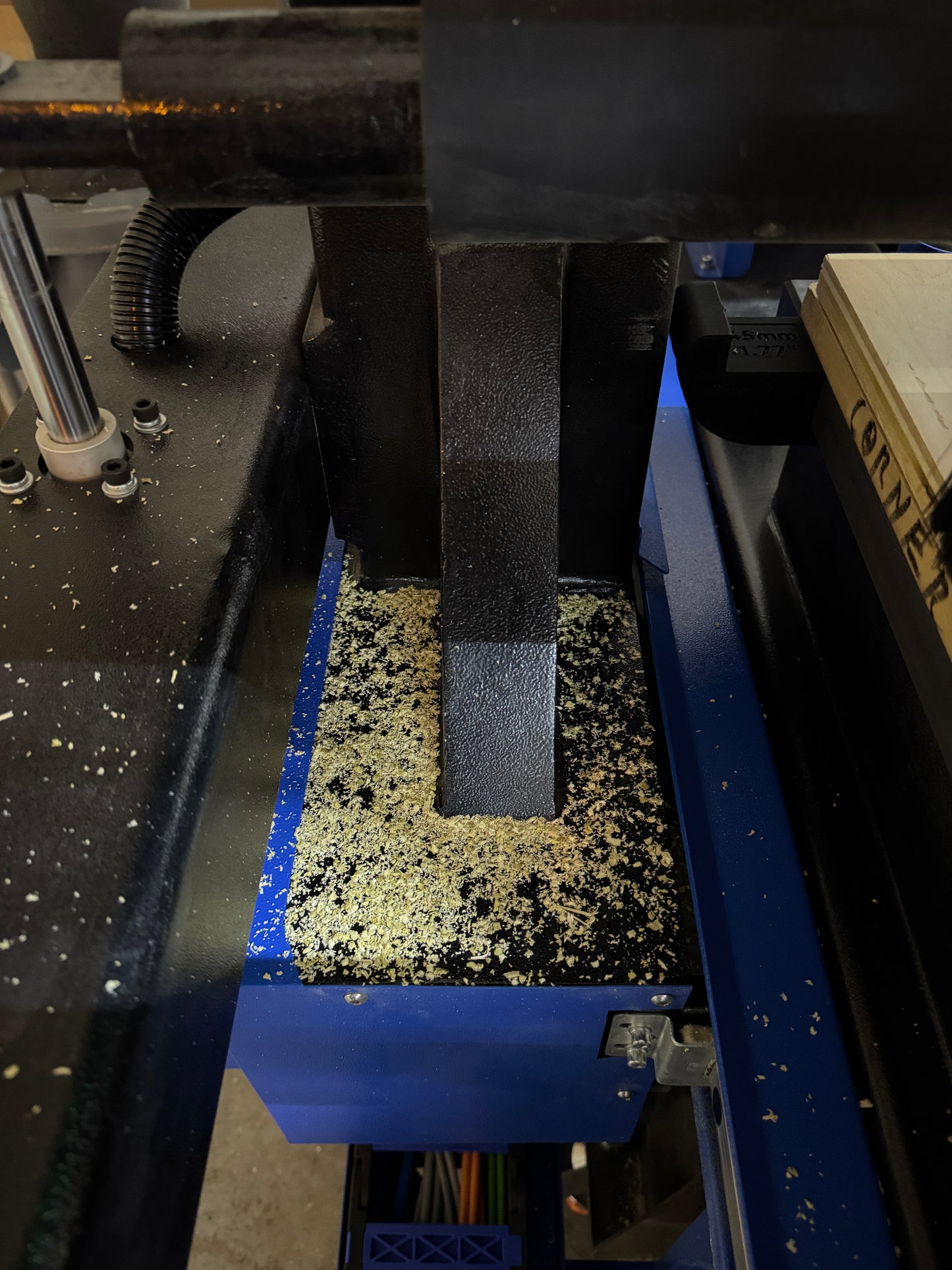

This set of brackets fixes a common issue with CNC machines: the dust and debris that gets shot out while cutting along the edge of sheet goods.

The problem arises because most dust boots aren't fully sealed against the table top, leaving gaps that allow wood chunks and fine dust to escape. The result? A messy workspace and poor air quality.

The Solution: DustEdge brackets extend a surface toward the edge of your machine, ensuring your dust boot stays fully supported during cuts and creating a more effective seal.

What’s Included:

- Standard Kit: Includes 5 brackets for CNC machines with an 8-foot table or 6 brackets for CNC machines with a 10-foot table, along with all the screws needed for installation. This setup supports one side of your CNC machine.

- Dual Kit: Includes double the brackets—10 for an 8-foot table or 12 for a 10-foot table—allowing you to install support strips on both sides of your CNC machine for maximum dust control. All necessary screws are included.

Installation Instructions:

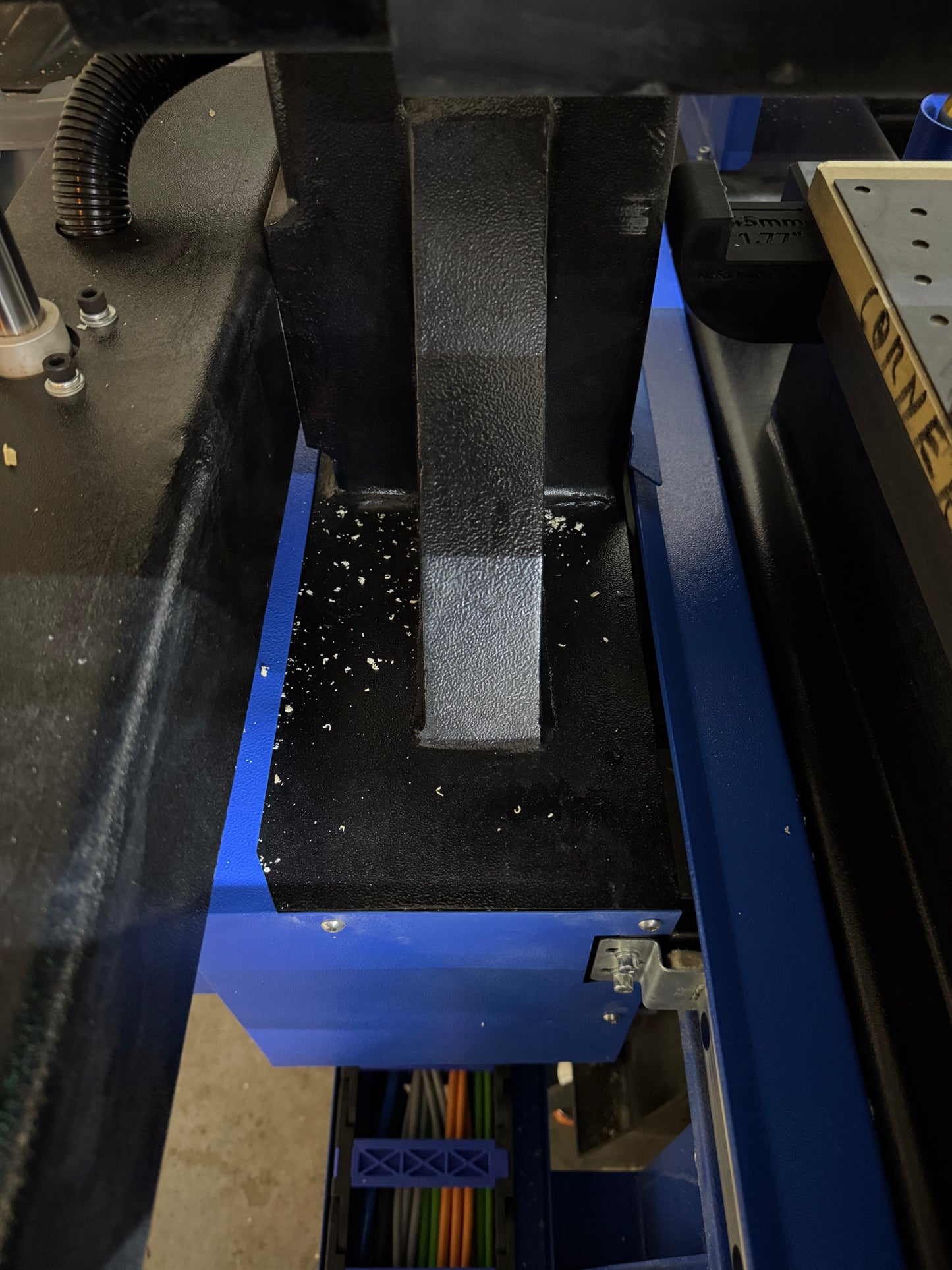

- Hold the top of the DustEdge bracket flush with the top of your vacuum plenum.

- Pre-drill a hole into the vacuum plenum.

- Screw the bracket securely in place using the provided screws.

- Repeat, mounting a bracket every two feet along the edge of the plenum.

- Measure the distance between the inside lip of the DustEdge brackets and the side of your plenum.

- Rip a piece of ¾” thick plywood to match the length of your CNC machine.

- Trim the plywood to accommodate any pop-up reference pins on your CNC.

- Press the sacrificial plywood board into place. The raised line on each bracket will hold it securely.

- (For the Dual Kit) Repeat steps on the opposite side of your machine for dual-sided dust protection.

With DustEdge installed, you’ll enjoy cleaner cuts, less mess, and improved dust collection on your CNC. Upgrade to the "Dual" variation for even more comprehensive dust control and efficiency!